PRODUCT OverviewPRODUCT CENTER

Flexible chemical composite hose supplier

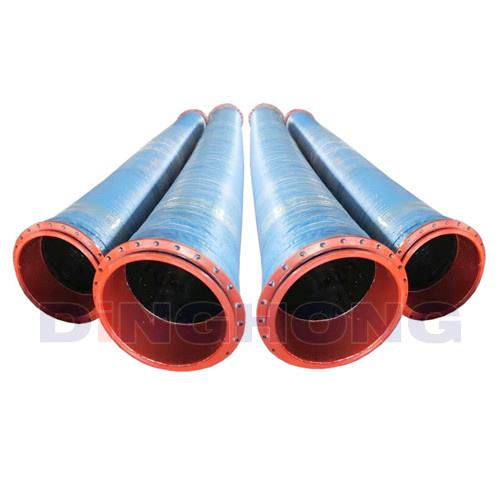

Flexible chemical composite hose also known as Wear-resistant Flexible Oil Composite Hose, Chemical Composite hose, Anti-static corrosion-resistant oil suction delivery hose, Petroleum transfer hoses, High temperature chemical hose etc, before the emergence of composite hoses, traditional rubber hoses and stainless steel hoses were commonly used in transferring liquid petrochemical products. In cases where hoses are often disassembled and moved, there are some obvious shortcomings of rubber hoses and stainless steel hoses. Chemical composite hoses are a new generation of safety hoses that has better overall performance and reduces cost. they are specifically designed for the replacement of rubber hoses and stainless steel hoses.

Chemical composite hose is composed of a variety of polymer material reinforcement layers, a sealing layer and an external anti-wear and anti-aging layer, fastened steel wire support.The construction of composite hoses is depending on the medium and application, with different wire helix materials (galvanized carbon steel, stainless steel etc), different types of films and fabrics (polypropylene, polyamide, ECTFE, polyester, fiberglass or aramid fiber).

Flexible chemical composite hose construction:

Multilayer polymer film, synthetic fabric reinforcement layer, inner and outer spiral metal wire, ends fittings.

Chemical composite hose specifications:

1. Hose size: 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300mm

2. Inner layer metal wire material: SS304/316, Galvanized steel wire, Polypropylene coating wire, Teflon coating wire etc

3. Outer layer metal wire material: SS304/316 or Galvanized steel wire

4. Inner lined layer material: Teflon, Polietilene, Nylon, PET etc

5. Working temperature:-40-130℃

6. Connect type: Threaded, Camlock quick coupling, Tri clamp, Union, Flange etc

7. Hose length can be specical customized according to user request

Chemical composite hose advantages:

1. Soft, good performance of expansion and bending, can eliminate pressure mutation

3. High temperature resistance, low temperature performance, uv resistance, anti aging

4. Electrostatic conductivity is good, can timely eliminate the tube wall electrostatic

The composite hose has the advantages of anti-static, anti-corrosion, safety, anti-bending, lightweight, easy to handle and easy to install, widely used in medicine, petrochemical, coating, tank truck, oil depot, wharf, sewage treatment, ships and other liquid or gas loading and unloading sites. For the transmission of expensive, toxic, flammable, corrosive, environmental pollution of liquid, gas and other highly dangerous areas to provide security.

Welcome to contact us for more details:

E-mail: info@apdhindustrial.com

Phone/WhatsApp/WeChat: +8615076851961